Introduction

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. As devices become smaller and more complex, traditional soldering methods often fall short. Enter Селективная пайка волной—a game-changing technology designed to deliver unmatched accuracy, reduce waste, and boost productivity. Whether you’re producing consumer electronics, automotive components, or industrial systems, selective wave soldering is the solution you need to stay ahead.

What is Selective Wave Soldering?

Selective wave soldering is an advanced soldering process that targets specific areas of a printed circuit board (PCB) with a controlled wave of solder. Unlike conventional wave soldering, which covers the entire board, this method uses precise nozzles to apply solder only where needed. This minimizes thermal stress, reduces solder consumption, and eliminates defects such as bridging or shadowing.

Why Choose Selective Wave Soldering?

1.Precision and Flexibility

With programmable soldering nozzles, selective wave soldering adapts to any PCB design—even those with mixed technology or high-density components. It ensures consistent results for through-hole and surface-mount components alike.

2.Cost Efficiency

By applying solder selectively, manufacturers save up to 50% on solder material and reduce energy consumption. The process also lowers rework rates, cutting overall production costs.

3.Enhanced Quality

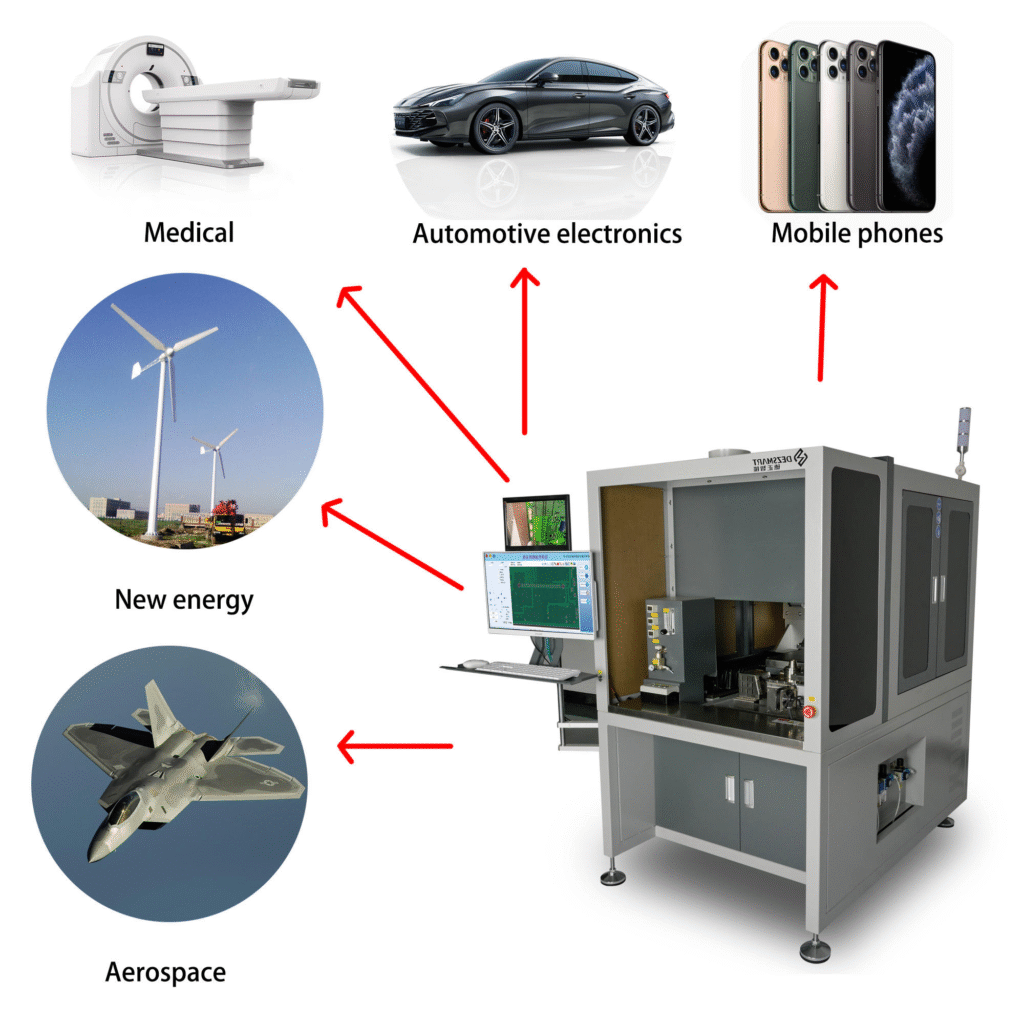

Controlled solder application minimizes the risk of defects, improving product reliability. This is critical for industries like automotive, aerospace, и medical devices, where failure is not an option.

4.Eco-Friendly Manufacturing

Reduced solder usage and waste make selective wave soldering a sustainable choice, aligning with global environmental standards.

Hot-Selling Countries and Trending Keywords

Selective wave soldering is gaining traction worldwide, especially in these tech-forward markets:

United States: “Automated soldering solutions,” “PCB assembly innovation,” “high-efficiency manufacturing.”

Germany: “Präzisionslöten,” “elektronische Fertigung,” “Industrie 4.0 Technologie.”

Japan: “選択的はんだ付け,” “高品質基板実装,” “省エネ製造.”

China: “选择性波峰焊,” “智能制造,” “高效焊接技术.”

South Korea: “선택적 웨이브 솔더링,” “정밀 PCB 어셈블리,” “자동화 생산.”

Ideal Applications

From consumer electronics like smartphones and wearables to automotive control units и industrial IoT devices, selective wave soldering is versatile enough to meet diverse manufacturing needs. It’s also perfect for low-to-medium volume production, offering quick changeovers and minimal downtime.

Why Partner with Us?

Our state-of-the-art selective wave soldering systems combine cutting-edge technology with user-friendly interfaces. With features like 3D programming, real-time monitoring, и closed-loop control, our machines ensure flawless soldering every time. Backed by global support and training, we help you streamline production and achieve superior results.

Conclusion

Don’t let outdated soldering methods hold you back. Embrace the future of electronics manufacturing with selective wave soldering. Enhance your product quality, reduce costs, and accelerate your time-to-market. Contact us today to learn how our solutions can transform your assembly line!

Ready to upgrade your soldering process? Visit our website or reach out to our experts for a customized demo. Let’s build the future, one connection at a time!