BGA soldering is a process used to attach BGA (Ball Grid Array) chips to circuit boards. Микросхемы BGA are characterized by having an array of solder balls arranged in a grid pattern on the bottom of the chip instead of pins around the periphery. The soldering of BGA chips presents challenges due to their unique packaging, making them more difficult to mount, solder, detect issues, and repair compared to other types of chips.

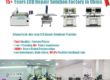

There are generally two methods for soldering BGA chips: using automatic BGA rework stations or manual soldering. Below, I’ll outline the method for soldering BGA chips using an automatic BGA rework station:

- Preparation: Prepare the automatic Станция доработки BGA и fix the BGA chip onto the PCB (Printed Circuit Board) fixture. Set the rework temperature curve according to the solder paste used. The melting point of leaded solder paste is around 183°C, while lead-free solder paste is around 217°C. Typically, the preheating temperature ramp rate is set between 1.2 to 5°C/s, the soak temperature is maintained between 160 to 190°C, and the peak temperature in the reflow zone is set between 235 to 245°C.

- Image Alignment: Utilize the vision alignment system to locate the position of the BGA chip that needs to be removed or soldered. The BGA rework station should have a high-definition imaging system for accurate alignment. Systems like Silman Tech’s automatic BGA rework station use point-to-point alignment, where the CCD automatically captures images of the pads and BGA solder balls, ensuring precise alignment.

- BGA Removal and Soldering: The automatic BGA rework station, such as the DEZ-R880A, can automatically detect and recognize different processes for removal and installation. Once the machine is heated, it can automatically separate the component from the PCB without manual intervention, preventing damage caused by improper handling during manual soldering. The machine can also perform automatic centering and soldering, achieving a 100% success rate in rework.

The advantages of using an automatic BGA rework station for BGA soldering include high levels of automation, avoidance of issues like inadequate temperature or mishandling during manual removal, automatic alignment, and heating, reducing the likelihood of misalignment during manual placement. This method is particularly suitable for medium to large enterprises, as it reduces the formation of defective products and significantly saves on labor costs.