In the electronics manufacturing industry, soldering efficiency and quality directly impact product performance and production capacity. As electronic products become increasingly complex, the limitations of traditional wave soldering are becoming more apparent—excessive thermal stress, damage to sensitive components, significant solder waste… Are these issues also troubling your production line?

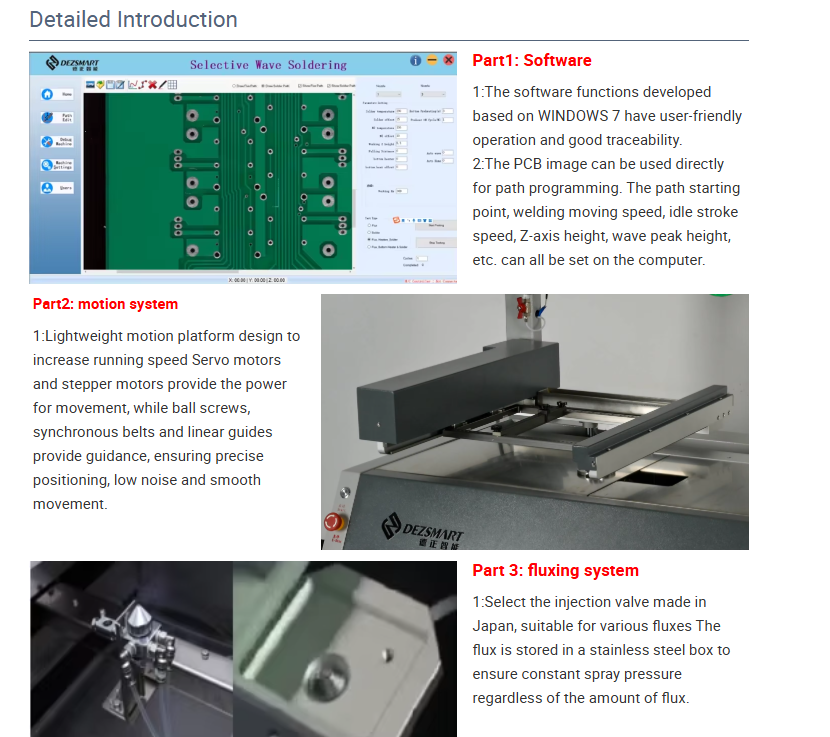

What is Selective Wave Soldering?

Selective Wave Soldering is an advanced soldering technology that uses precisely controlled micro-solder waves to target only specific areas requiring soldering. Unlike traditional full-wave soldering, it employs a programmable nozzle system for accurate and efficient soldering.

Real Customer Challenges and Solutions

Case 1: Automotive Electronics Manufacturer Faces Thermal-Sensitive Component Damage

A German automotive electronics supplier experienced performance degradation in temperature-sensitive components while producing ADAS control modules using traditional wave soldering. After implementing our selective wave soldering solution:

70% Reduction in Thermal Impact: Localized soldering significantly reduces thermal stress

25% Increase in Yield Rate: Dramatic decrease in damage to sensitive components

40% Energy Savings: Precision soldering substantially lowers energy consumption

Case 2: Medical Device Manufacturer Tackles High-Density PCB Soldering Challenges

A US medical device manufacturer encountered short-circuit issues between adjacent solder joints on high-density PCBs for portable monitoring devices. Our solution provided:

±0.1mm Soldering Precision: Accurate targeting of solder points

90% Reduction in Short Circuits: Minimal interference between adjacent joints

Enhanced Flexibility: Multiple board types processed without fixture changes

Case 3: Consumer Electronics Company Reduces Solder Waste Costs

A Korean consumer electronics company sought to decrease solder usage for cost reduction. Our selective wave soldering achieved:

60% Less Solder Consumption: Precise control of solder volume

50% Lower Maintenance Costs: Significant reduction in dross formation

Core Technical Advantages of Our Selective Wave Soldering

- Intelligent Programming System: User-friendly interface with CAD data import

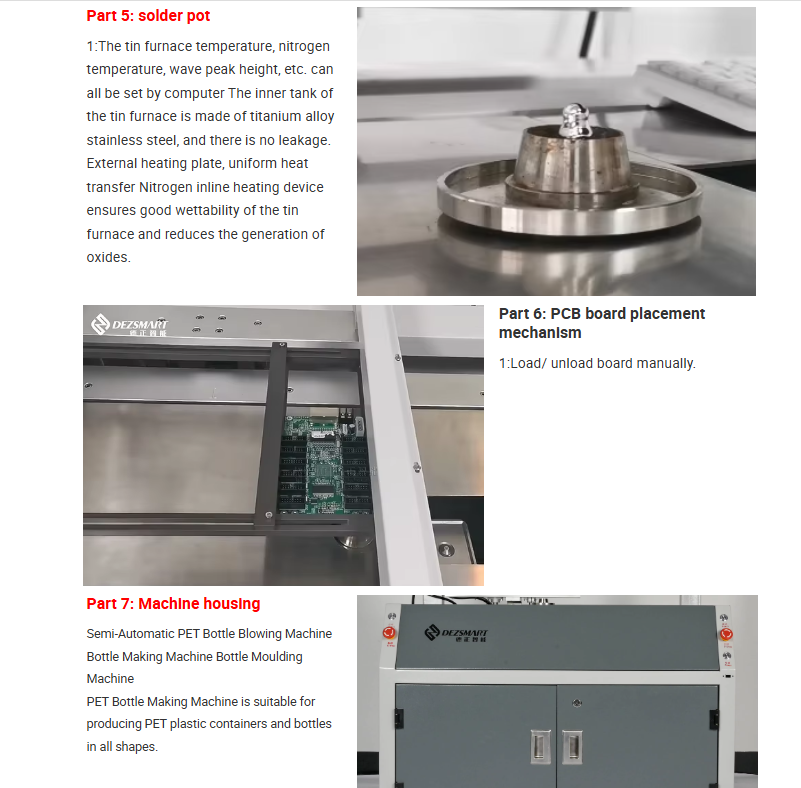

- Multi-Axis Precision Control: High-accuracy robotic arms ensure positioning

- Adaptive Wave Height Control: Automatic adjustment based on PCB thickness

- Nitrogen Protection Option: Reduces oxidation for better joint quality

- Real-Time Monitoring: Complete process tracking with data traceability

Industry Applications

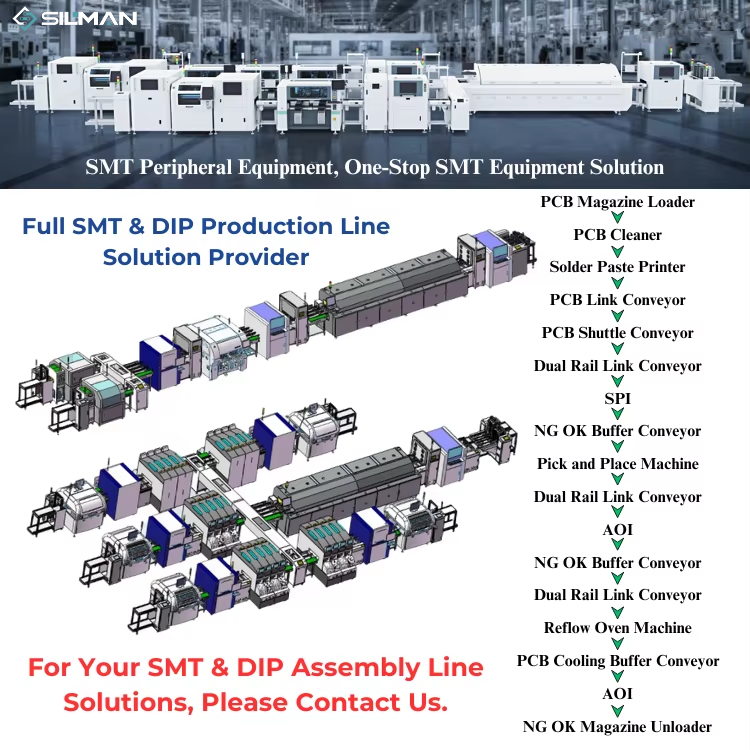

Our selective wave soldering equipment has been successfully implemented in:

Automotive Electronics (ECUs, sensors)

Medical Devices (monitoring equipment, implants)

Industrial Controls (PLCs, inverters)

Telecommunications (base station components)

Aerospace and Defense (avionics systems)

Global Success Keywords

United States: “precision soldering solutions,” “automated manufacturing technology,” “electronics production innovation”

Germany: “industrielle löslösungen,” “präzisionslöttechnik,” “elektronikfertigung effizienz”

Japan: “高精度はんだ付け,” “選択的フローソルダリング,” “電子部品実装技術”

South Korea: “정밀 솔더링 솔루션,” “선택적 웨이브 솔더링,” “전자제품 생산성 향상”

Ready to Transform Your Production Line?

Our selective wave soldering solutions are helping manufacturers worldwide overcome production challenges while improving quality and reducing costs. Whether you’re dealing with mixed-technology boards, thermal-sensitive components, or seeking to optimize resource utilization, our technology provides the precision and flexibility you need.

Contact us today to schedule a demonstration and learn how selective wave soldering can solve your specific production challenges while positioning your manufacturing process for future success in the competitive global electronics market.

SEO Keywords: Selective wave soldering, precision soldering solutions, wave soldering automation, PCB assembly technology, electronics manufacturing efficiency, soldering quality improvement, industrial soldering systems, automotive electronics soldering, medical device soldering solutions, smart manufacturing soldering