In the fast-paced world of electronics manufacturing and repair, precision and efficiency are non-negotiable. Whether you’re tackling laptop motherboard repairs in India, optimizing SMT production lines in the USA, or fixing automotive electronic components in Vietnam, Estações de retrabalho BGA stand as the backbone of reliable electronic maintenance. Designed to address the most complex ball grid array (BGA) component issues, our advanced rework stations combine cutting-edge technology with user-centric design, empowering technicians and manufacturers across the globe to overcome repair hurdles and boost productivity.

Core Features: Engineered for Precision and Versatility

Our BGA rework stations are equipped with a suite of high-performance features that redefine the standards of electronic rework. These capabilities ensure consistent, high-quality results across diverse applications—from consumer electronics to aerospace components.

1. Advanced Heating Systems for Uniform Thermal Control

Featuring three independent heating zones (top hot air heater, infrared heater, and bottom preheater) with fully programmable temperature curves, our stations deliver uniform heat distribution that eliminates the risk of overheating or thermal stress. The infrared heating technology targets BGA components precisely, minimizing heat impact on surrounding sensitive parts like capacitors and crystals . With temperature accuracy of ±3℃ and real-time thermocouple monitoring, technicians can easily handle large BGAs (up to 120*120mm) and complex PCBs without warpage or pad damage .

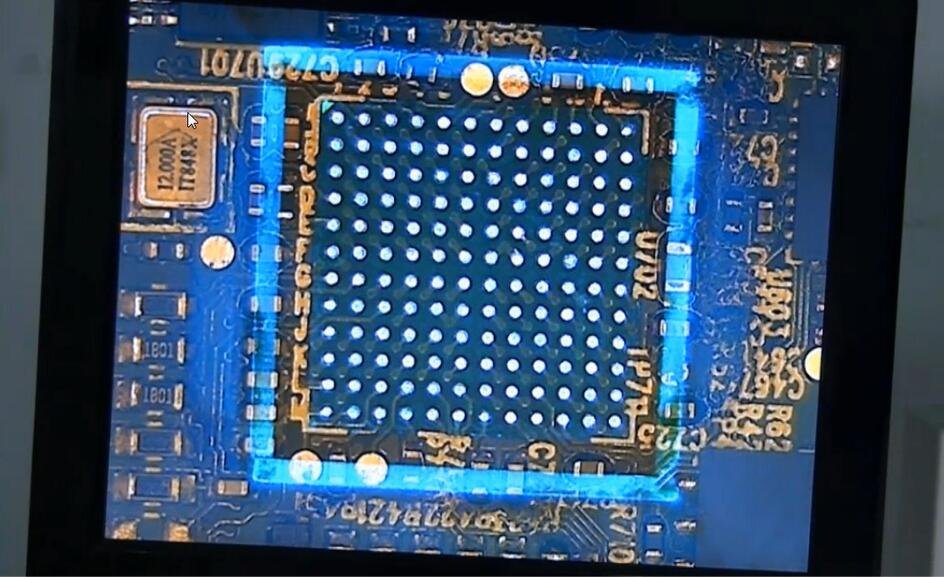

2. High-Precision Optical Alignment System

Equipped with high-resolution cameras and laser positioning technology, our rework stations enable micron-level alignment accuracy. The XYZ adjustment controls allow for easy fine-tuning, ensuring perfect alignment between BGA solder balls and PCB pads—critical for preventing shorts, open circuits, and component failure . This feature is particularly valuable for repairing fine-pitch BGAs, CSPs, and PoP (Package-on-Package) configurations common in modern smartphones and tablets.

3. User-Friendly Automation and Safety Features

Our semi-automatic and fully automatic models streamline the rework process with one-touch operation for component removal, placement, and soldering . The intuitive touchscreen interface lets users store and recall custom temperature profiles, while built-in safety mechanisms—including emergency stop buttons, overheat alarms, and automatic power-off—ensure operator and equipment safety . Password protection for temperature parameters and barcode management also support traceability requirements, essential for industrial production environments in the USA and Europe.

4. Versatile Compatibility and Accessories

Designed to accommodate a wide range of components and PCB sizes, our BGA rework stations come with a full set of interchangeable nozzles for different BGA types . They support rework of laptops, desktops, Xbox consoles, communication boards, automotive ECUs, and even aerospace components . This versatility makes them the go-to solution for repair shops, electronics manufacturers, and maintenance teams in India, Vietnam, Saudi Arabia, and beyond.

Solving Your Toughest Electronic Rework Challenges

Electronic technicians and manufacturers worldwide face common pain points that hinder productivity and profitability. Our BGA rework stations are specifically engineered to address these issues head-on:

Challenge 1: Costly Board Replacements and Downtime

Sending defective PCBs to external repair services or replacing them entirely leads to long downtime and high costs. Our BGA rework stations enable on-site repair, reducing turnaround time by up to 70% and cutting repair costs significantly. For example, Indian electronics manufacturers have reported saving thousands of dollars annually by reworking defective motherboards instead of replacing them .

Challenge 2: Damage to Adjacent Components During Rework

Traditional rework methods often damage nearby sensitive components due to uncontrolled heating. Our targeted heating systems and thermal insulation solutions protect adjacent parts, ensuring no collateral damage during BGA removal and soldering . This is a game-changer for repairing dense PCBs in automotive electronics, a growing market in Vietnam and the USA.

Challenge 3: Poor Rework Quality and Reliability

Inconsistent heating and misalignment often result in rework failures, leading to repeated repairs and customer complaints. Our precise temperature control and optical alignment system ensure a 99% first-pass rework success rate, improving product reliability and customer satisfaction. This has made our stations a top choice for medical device manufacturers, where precision is non-negotiable .

Challenge 4: Handling Complex BGA Configurations

Large BGAs, bottom-filled BGAs, and double-sided PCBs with mirror BGAs present unique rework challenges. Our advanced heating systems and customizable fixtures handle these complex configurations with ease, eliminating warpage and ensuring strong solder joints . For US-based aerospace component refurbishers, this capability has been critical for meeting strict industry standards .

Trusted by Global Markets: Top Choice in High-Demand Regions

Our Dezsmart|Silman BGA rework stations are among the most sought-after solutions in the world’s fastest-growing electronics markets. As per global import data, the USA, Korea, UK and Vietnam are the top importers of BGA rework stations, driven by booming electronics manufacturing and repair industries . Whether you’re searching for “BGA rework station Korea”, “precision BGA repair USA”, or “SMT rework solution Vietnam”, our products consistently rank among the top search results for their reliability and performance.

We also cater to growing demand in Germany, France,Malaysia,Thailand and so on. Our global support team provides timely technical assistance and training, ensuring you get the most out of your equipment, no matter where you are.

Elevate Your Rework Capabilities Today

In an industry where precision directly impacts profitability, choosing the right BGA rework station is essential. Our advanced solutions combine state-of-the-art technology, user-friendly design, and global compatibility to solve your toughest rework challenges—from small repair shops in Malaysia to large-scale manufacturing facilities in the USA.

Ready to boost efficiency, reduce costs, and deliver consistent, high-quality rework? Explore our range of BGA rework stations and find the perfect solution for your needs. Contact our team today for a personalized consultation and free demo.

Keywords: BGA rework stations, precision BGA repair, SMT rework solution, BGA rework station Malaysia, BGA repair USA, Vietnam electronic repair, infrared BGA rework, optical alignment BGA station