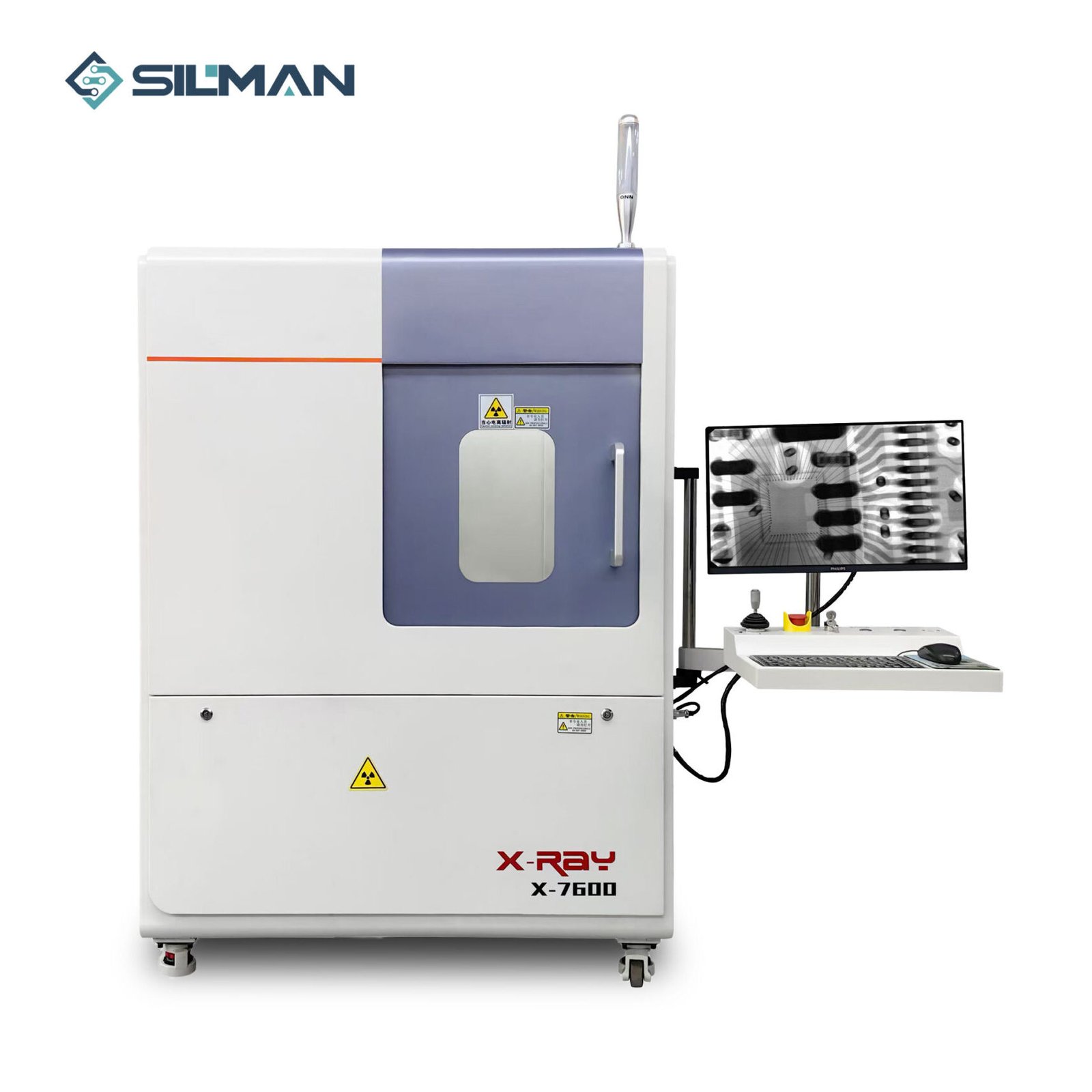

X-RAY Intelligent Component Counting Machine

The system of this series of equipment is primarily composed of seven main components: X-ray source, image imaging unit, computer image processing system, mechanical system, electrical control system, safety protection system, and warning system. It integrates modern non-destructive testing, computer software technology, image acquisition and processing technology, mechanical transmission technology, and AI algorithms. It covers the four major technical fields of optics, mechanics, electronics, and algorithms. By exploiting the differences in X-ray absorption caused by different materials or thicknesses, the internal components of electronic device trays are imaged and counted for detection.

An X-RAY Intelligent Component Counting Machine is a specialized device typically used in industrial and manufacturing settings, such as electronics assembly or quality control. These machines use X-ray technology to accurately count small components, such as resistors, capacitors, and other electronic parts, in bulk.

Key Features of an X-RAY Intelligent Component Counting Machine:

1. X-Ray Imaging Technology:

* The machine uses X-ray imaging to view the components inside sealed packaging (such as bags or boxes) without opening them. This allows for accurate counting of components based on their shape, size, and density.

* X-ray technology provides high-resolution imaging that enables precise detection and analysis of individual components, even in mixed or complex packages.

* The machine can automatically identify and count small components based on their X-ray signature. This significantly reduces human error, ensuring high accuracy in the counting process.

* It can handle bulk counts in seconds, which is far more efficient than manual counting or traditional mechanical counters.

* The machine provides real-time results, including detailed counts, batch information, and quality control metrics.

* It can be integrated with other systems (like inventory management software) for seamless tracking and reporting.

* Since X-ray imaging is non-destructive, components do not need to be unpacked or handled, minimizing the risk of damage or contamination.

* Advanced X-ray counting machines often integrate artificial intelligence (AI) and machine learning algorithms that learn and adapt to new components over time, improving counting accuracy and efficiency.

* Electronics Manufacturing: Used for counting components like resistors, capacitors, diodes, and chips in production lines.

* Speed and Efficiency: The ability to count large quantities of small components in a short amount of time without manual intervention.

* Cost-Effective: In the long term, the machine can reduce labor costs and waste from incorrect parts counts or faulty inventory.

An X-Ray Intelligent Component Counting Machine is a powerful tool for industries that require high-precision counting of small components, especially where speed, accuracy, and efficiency are crucial. It leverages cutting-edge X-ray imaging and AI technologies to automate the counting process, reducing human errors and ensuring high-quality control.

| General Specification | |

|---|---|

| Working mode | Off-line |

| Dimensions(mm) | 800(W)X1380(D)X1950(H) |

| Gewicht | Approx. 800 KG |

| Stromversorgung | 110~220VAC 50/60Hz, 1.5KW |

| System Computer | |

| Industrial PC | Industrial PC with Intel i7 processor (64bit) |

| Operating System | Window 10 OS |

| Display | 27" FHD LCD Display |

| Storage System | |

| RAM:16GB, HDD:1TB + SSD:256G | / |

| Accessories Included | |

| Handheld Barcode scanner | / |

| Label printer | / |

| Inspection Capabilities | |

| Tape & reel size | 7" ~ 17" |

| Scan height | ≤80mm |

| Max inspection speed | 7”~17” |

| Tape & Reel | <10s> |

| Min component size | 01005 |

| Inspection accuracy | ≥99.99% |

| X-Ray Tube | |

| Type | Closed tube |

| Max Voltage | 50KV |

| Max. Current | 1000 μA |

| Focus spot size | 0.03mm |

| Imaging System | |

| Type | Flat Panel Detector (FPD) |

| Effective detection range: | 430mmx430mm |

| Pixel matrix | 3072*3072 pixel |

| Pixel size | 139μm |

| Frame Rate | 6fpsv |

| AD Conversion | 16 bits |

| Detectable Package | |

| Chip, Bulks, ESD packages, JEDEC Tray, Tube, Transistor. | / |

| Detectable Components | |

| Capacitors, resistors, inductors, beads, crystals, transistors, diodes, FETs, various types of resistors, bile capacitors, detectable connectors, integrated circuit chips, etc | / |

| Database | |

| Support connection with MES, ERP, and WMS Intelligent | / |

| Safety System | |

| Standard | Conformed to FDA-CDRH regulation CFR 21 1020.40 subchapter for cabinet x-ray systems. |

| X-ray emission | ﹤ 1μSv/h (FDA-CDRH regulation CFR 21 1020.40 subchapter standard required < 5μSv/h) |

| Authority management | Fingerprint and password assessing system. |

| Shielded cabinet protection against radiation leakage | |

| Real time radiation leakage monitoring meter | |