Is your once-pristine LCD screen marred by unsightly color lines, white spots, or brightness issues? Don’t despair! This blog post introduces you to the innovative world of LCD laser repair machines, a powerful solution for restoring your screen to its former glory.

What Can a Laser Repair Machine Do?

Laser repair machines are specifically designed to tackle a variety of LCD screen problems, including:

- Color Line Woes: Horizontal and vertical lines, white spots, and brightness issues caused by short circuits or impurities can often be addressed using laser technology.

- Extensive Compatibility: These machines support various display types like TFT-LCD, IPS, LTPS, and even OLED.

- Brand Agnostic: Leading brands like LG, Samsung, Sony, and many more are compatible with laser repair, offering a wide range of application.

- Size Doesn’t Matter: From small screens to massive 100-inch displays, laser repair machines can handle a variety of sizes.

- High-Resolution Repair: These machines support repairs on both 2K and 4K LCD screens, ensuring exceptional image quality after repair.

Who Benefits from Laser Repair Machines?

Laser repair machines are ideal for various users in the LCD industry:

- Large-Scale Manufacturers and TV Factories: Maintain production efficiency by repairing faulty LCD panels instead of discarding them.

- After-Sales Service Companies and Screen Maintenance Businesses: Offer high-quality repair services to extend the lifespan of LCD screens.

- LCD TV Distributors: Provide exceptional after-sales service by repairing screens instead of replacements.

- Authorized Service Centers of LCD TV Brands: Equip yourselves with the latest technology for efficient and reliable repairs.

How Does it Work?

The repair process involves a meticulous three-step approach:

- Inspection: A high-definition microscope precisely identifies the faulty area and control circuits using advanced imaging.

- Repair: A powerful laser beam performs micro-welding or soldering to reconnect damaged areas with functioning control circuits, restoring the voltage signal.

- Testing: Finally, the repaired area is thoroughly evaluated to ensure successful repair.

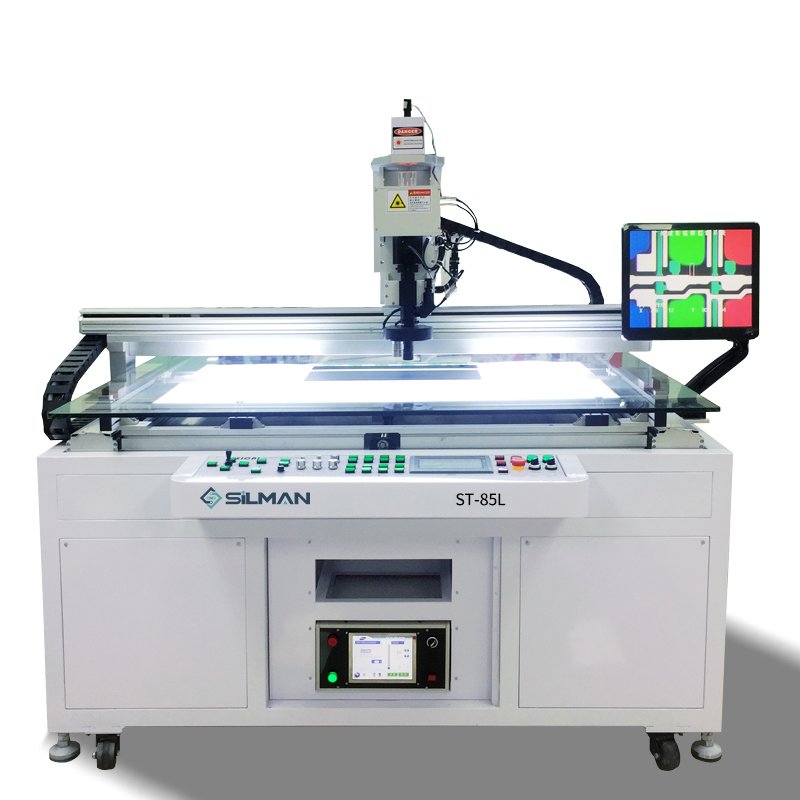

Features of Laser Repair Machines:

- Precise Control: Electrically controlled microscopes and laser focus ensure pinpoint accuracy during repairs.

- Versatility: Multiple laser working size options provide flexibility for different repair scenarios.

- Spacious Work Area: Large working stages accommodate various screen sizes.

- Stability Matters: Built-in damping devices minimize image shaking for precise repairs.

- Adjustable Speed: XYZ axis movement speeds can be tailored for optimal control.

- Fast Focus: Automatic lens switching and rapid focus capabilities enhance workflow efficiency.

- Crystal Clear Vision: High-resolution CCD monitors provide excellent image quality during repairs.

Considering an LCD Laser Repair Machine?

SilmanTech is your one-stop shop for top-of-the-line laser repair machines . Visit our website (https://silmantech.com/product/tv-laser-repair-machine/) to explore our advanced machines and breathe new life into your LCD screens!

Supported Brands (and more): LG, Samsung, Sony, Hisense, TCL, Panasonic, Philips, Asus, Lenovo, Acer, HP