Introduction to SMT X-Ray machine

An SMT X-Ray machine refers to a specialized X-ray inspection system used in the Surface-Mount Technology (SMT) industry to inspect and analyze the internal structure of electronic components and circuit boards. In the context of SMT manufacturing, the X-ray machine plays a critical role in ensuring the quality and reliability of solder joints and component placements on printed circuit boards (PCBs).

Purpose and Use:

1. Inspection of Hidden Features:

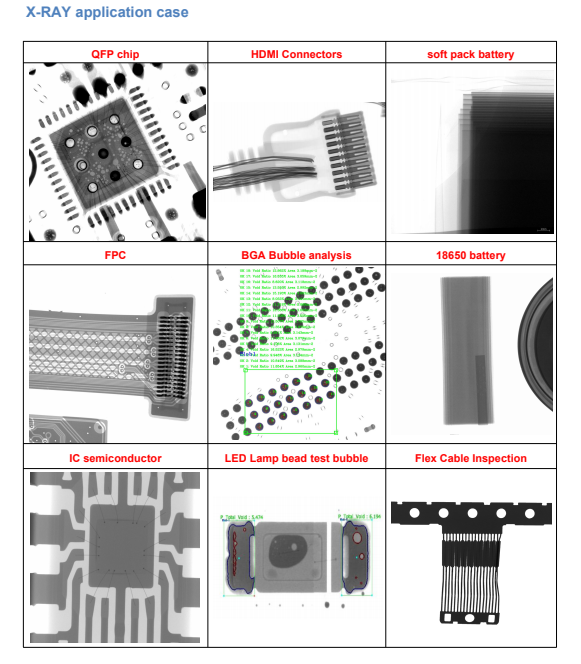

* Solder Joints: SMT components, especially those that are small or have hidden leads (e.g., BGA—Ball Grid Array, QFN—Quad Flat No-lead), can have hidden or hard-to reach solder joints. These joints can be inspected non-destructively using X-rays.

* Internal Package Structure: For components like BGAs, CSPs (Chip-on-Substrate), and other advanced packages, the X-ray machine allows inspection of the internal connections (e.g., the solder balls inside the BGA package) that cannot be seen with optical inspection methods.

2. Defect Detection:

* Cold or Open Solder Joints: The machine can detect weak solder joints that may have insufficient solder, leading to potential connection issues.

* Voids: It can identify voids or air pockets inside solder joints, which can affect electrical conductivity and reliability.

* Bridging: In the case of high-density components, the X-ray can identify solder bridges (unintended connections between two solder joints).

* Using X-ray inspections, manufacturers can optimize their soldering process to improve yield rates and reduce defects, thus saving costs associated with rework and returns.

Features to Look for in SMT X-Ray Machines:

* High Resolution: Fine resolution is crucial for detecting micro-scale defects in components like BGAs.

* Automated Inspection: Many modern systems offer automated defect detection software that can flag potential issues without human intervention.

* Real-Time Imaging: Some machines offer real-time or near-real-time imaging, which allows for faster decision-making and process adjustments.

* Quality Control: Ensures that the products meet the required standards of performance and reliability before they are sent to customers or assembled into larger systems.

SMT X-Ray machines are vital tools for inspecting advanced packaging technologies, improving manufacturing processes, and ensuring high-quality products in the electronics industry. By providing non-destructive analysis of solder joints, hidden internal connections, and other critical features, they help manufacturers identify defects early and maintain high reliability in their assemblies.

X7600 SMT X-Ray Inspection System Machine

| Classification | Artículo | Type | Parameters and Functions |

|---|---|---|---|

| Hardware Configuration | X-ray Source | Brand Type | Hamamatsu, Japan, Closed Microfocus X-ray Source |

| Voltage Current | 130kv,10-300uA | ||

| Focus Size | 5 μm | ||

| Maxi Power | 39W | ||

| Imaging Unit | Brand Type | iRAY,Amorphous Silicon Flat Panel Detector |

|

| Área de imágenes | 130mm×130mm | ||

| Tamaño de la unidad fotosensible | 85μm | ||

| Matriz de píxeles | 1536×1536 | ||

| Resolución | 5.8Lp/mm | ||

| Image Frame Rate | 20fps | ||

| Tilt Angle | 0-90° viewing angle (45° to the left and right) | ||

| Magnification Ratio | Geometric magnification of 150 times | ||

| Computer | Host Brand | Advantech Industrial Computer |

|

| Industrial Computer Configuration | CPU:I5 7700 RAM:8G, HDD:1TB |

||

| Monitor | 24" FHD LCD Display | ||

| Loading Platform | Loading Area | 520mm×520mm | |

| Maxi Inspection Area | 510mm×450mm |

||

| Motion Travel (Z-axis) | Detection Panel Z1=300mm,X-ray Source Z2=300mm | ||

| Motion Travel (X-axis) | X axis=510mm,Y axis=450mm |

||

| Maxi Sample Peso | 12kg |

||

| Movement Método de control | Joystick, Mouse, and Keyboard Tri-combination |

||

| Navigation System | Configuration | Hikvision High Definition Camera |

|

| Software system | Software Introduction | Intellectual Property | Independently developed with proprietary software intellectual property. |

| Software Functions | Automatic Image Setting | Recording position coordinates and parameter information of characteristic | |

| Automático Navigation Functionality | Facilitate quick movement to inspection points |

||

| Calculation Feature | Capable of measuring bubbles in electronic/semiconductor products |

||

| Algorithm Model | Customizable detection algorithm models based on requirements |

||

| Location Editing Functionality | Easily achieve multi-point position detection |

||

| Machine parameters | Peso | Peso | About 1650Kg |

| Fuente de alimentación | Fuente de alimentación | 220V/50Hz | |

| Maxi Power | Maxi Power | 2.0KW | |

| Equipment Dimensiones | Equipment Dimensions | 1400mm(L) * 1350mm(W) * 1750mm(H) | |

| Radiation Leakage Dose | Radiation Leakage Dose | < 0.5μSv / h |