In today’s rapidly evolving electronics manufacturing industry, achieving ultimate precision, exceptional efficiency, and reliable quality is the core of maintaining competitiveness. As printed circuit board (PCB) designs become increasingly miniaturized and complex, traditional soldering processes are no longer sufficient. Dezsmart|Silman offers cutting-edge Selektives Wellenlöten solutions, opening a new chapter of high-precision, flexible, and low-cost manufacturing for your business.

Why Choose Dezsmart|Silman Selective Wave Soldering?

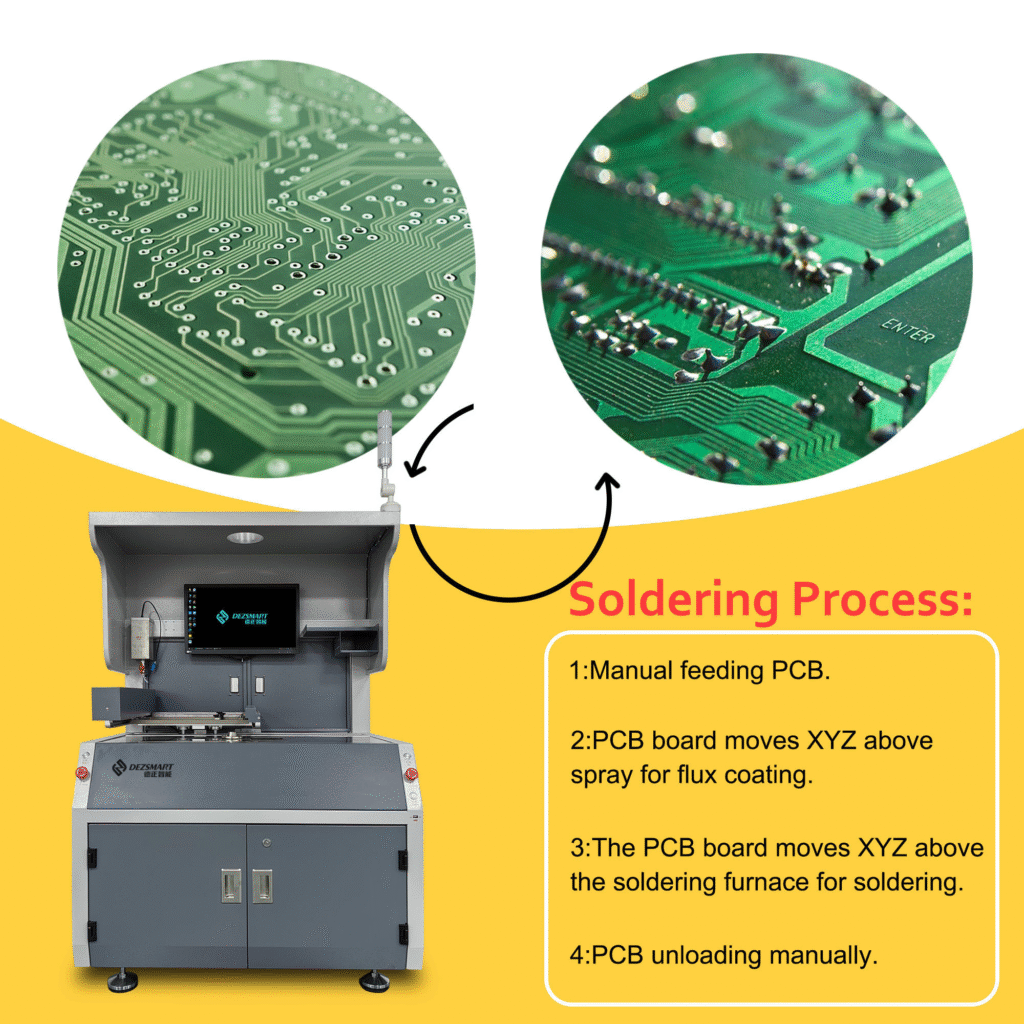

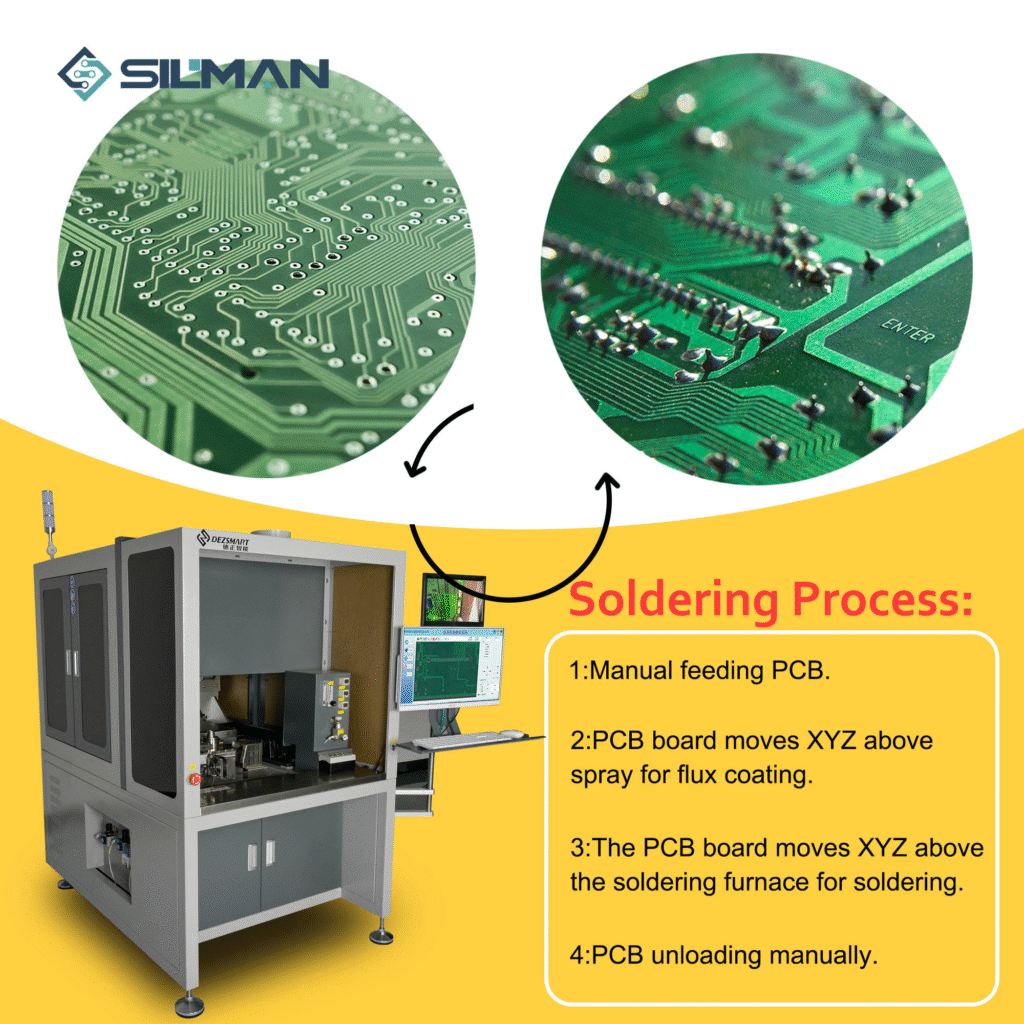

We understand the challenges of modern electronic assembly. Our selective wave soldering systems move beyond the conventional “immersion-style” soldering approach, utilizing highly precise micro-solder waves to programmatically solder specific through-holes or pins on PCBs. This delivers revolutionary advantages:

Unmatched Precision: Effectively prevents bridging, skipped soldering, and is especially suitable for high-density, mixed-technology, and thermally sensitive components.

Significant Cost Reduction: Solder usage can be reduced by up to 70%, and consumable (flux) consumption is greatly decreased, directly improving profit margins.

Enhanced Product Reliability: Localized heating minimizes thermal stress, protecting surrounding precision SMD components and PCB substrates, reducing the risk of failure.

Ultimate Flexibility: Quick changeover times, perfectly suited for R&D prototyping, small-to-medium batch production, and high-mix manufacturing—an ideal choice for Industry 4.0 smart manufacturing.

Star Product Series to Meet Diverse Needs

1. DEZ-3200 Selective Wave Soldering System

Key Features: A cost-effective entry-level solution. Although it does not include an independent preheating function, its optimized nozzle design and precise solder wave control already deliver excellent performance for most conventional soldering challenges, providing stable and reliable soldering quality.

Ideal For: Small-to-medium scale production lines with budget constraints, products with moderate thermal sensitivity, and those seeking process upgrades.

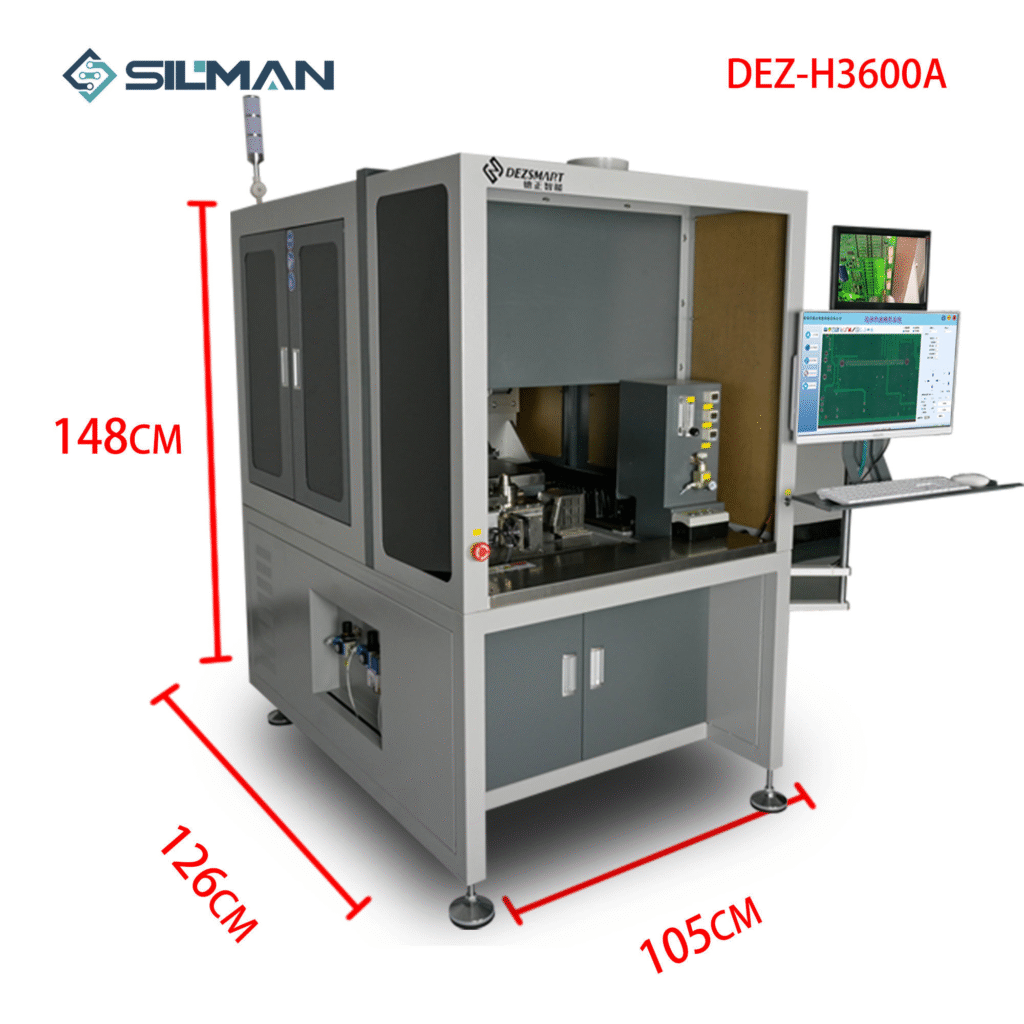

2. DEZ-H3600A Advanced Selective Wave Soldering System

Key Features: Flagship performance, all-around solution. Equipped with an intelligent preheating module, it enables precise and controllable preheating profiles, ensuring proper flux activation and even PCB temperature rise. This significantly improves solder wettability and eliminates cold solder joints.

Offline Design: Operates as a standalone workstation without modifying existing production lines. Highly flexible deployment makes it the ultimate tool for enhancing key process capabilities or establishing dedicated high-reliability soldering lines.

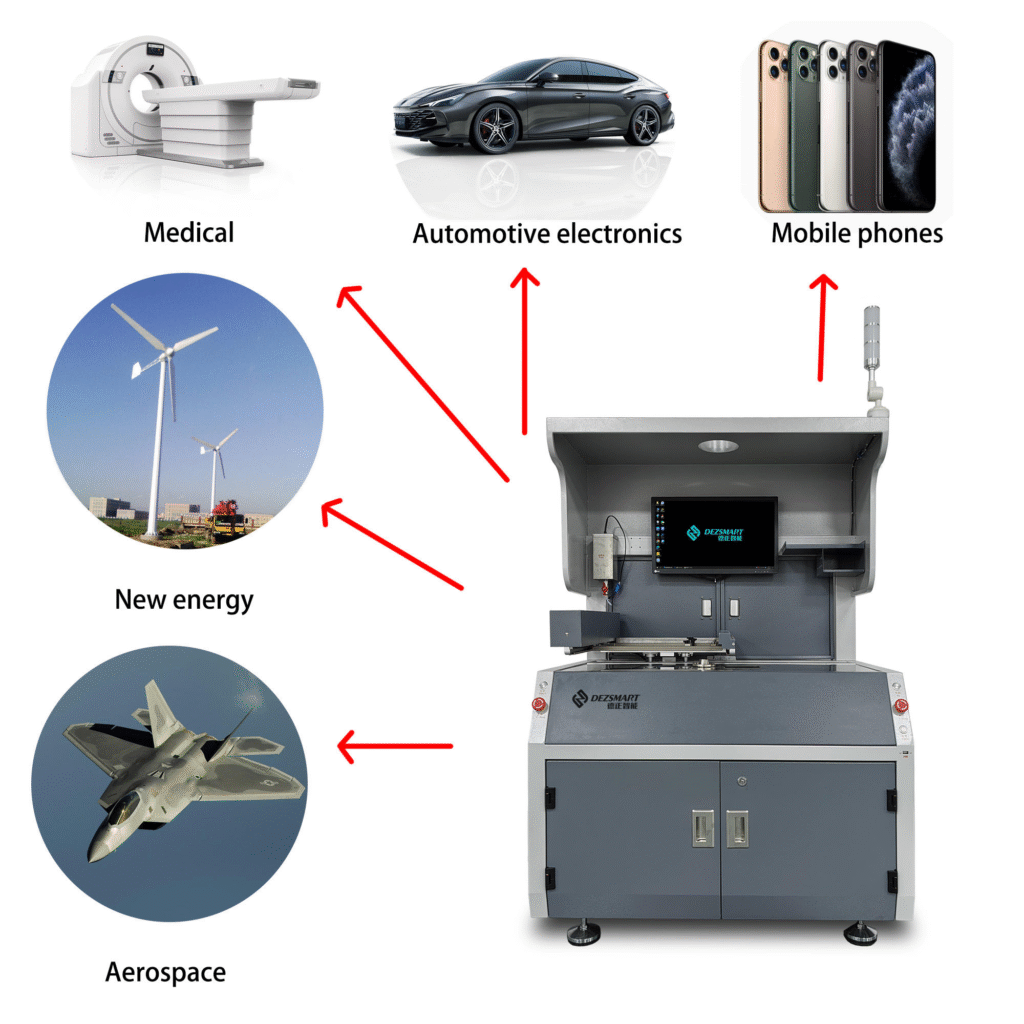

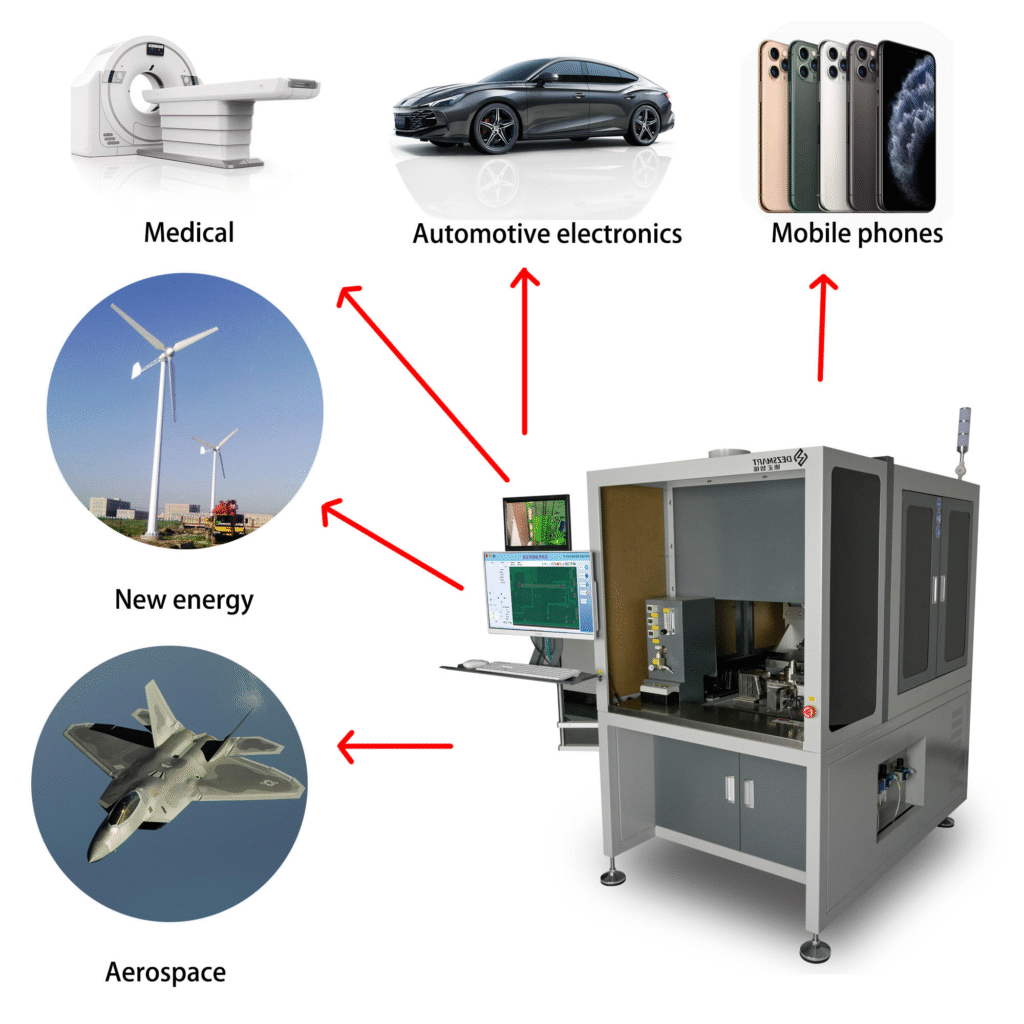

Ideal For: Automotive electronics, aerospace, high-end communications, medical devices, and other fields with stringent soldering quality requirements.

Globally Popular, Powering Smart Manufacturing

Dezsmart|Silman equipment has become the trusted partner of leading manufacturers worldwide, generating significant demand in key markets and aligning with high-search-volume keywords:

United States Market: “Selective soldering machine”, “high-precision PCB assembly”, “cost-effective soldering solution”, “DEZ-3200”, “DEZ-H3600A”

German Market: “Selektivlötanlage”, “Löttechnik für Elektronikfertigung”, “Präzisionslöten”, “Industrie 4.0 Lötlösung”

Japanese Market: “選択的はんだ付け機”, “高品質はんだ付”, “省エネ製造設備”, “DEZ-H3600A オフライン”

Chinese Market: “选择性波峰焊设备”, “智能焊接机器人”, “精密电子制造”, “DEZ-3200性价比”, “离线式预热焊接”

South Korean Market: “선택적 솔더링 머신”, “정밀 PCB 어셈블리”, “자동화 솔더링 시스템”

Wide Applications, Driving Industry Innovation

Whether for automotive electronic control units, industrial power modules, LED lighting boards, or consumer electronics, Dezsmart|Silman’s selective wave soldering systems deliver perfectly tailored solder joints. We provide not only equipment but also comprehensive process support and a global service network to ensure worry-free production.

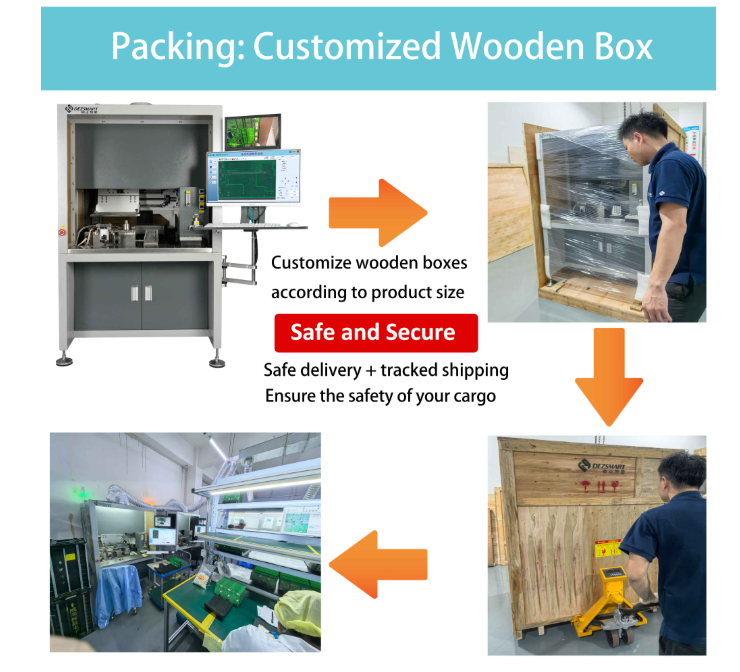

Choosing Dezsmart|Silman means more than selecting a machine—it means choosing a manufacturing partner committed to your long-term success.

Take Action Now and Start Your Soldering Revolution!

Visit our official website to learn more about our products, or contact our technical experts to arrange a personalized demo and process evaluation.