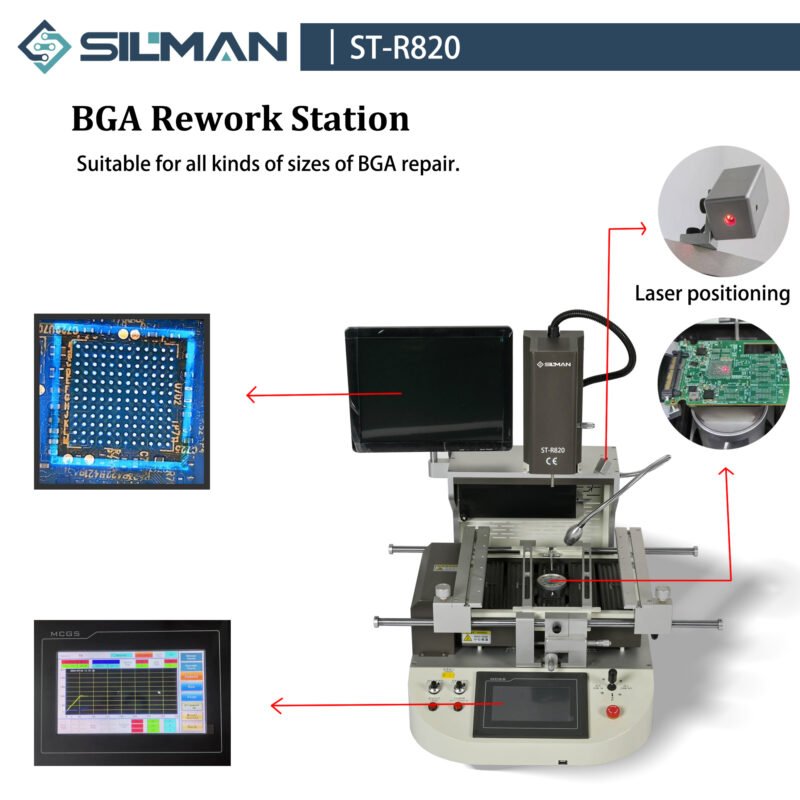

Overview

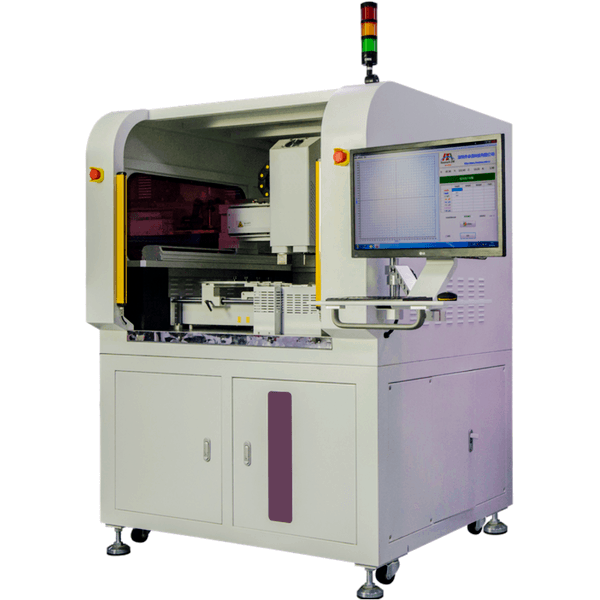

Semi-automated rework system for normal SMD, BGA, QFP, CSP, sockets, Micro-SMD components etc.

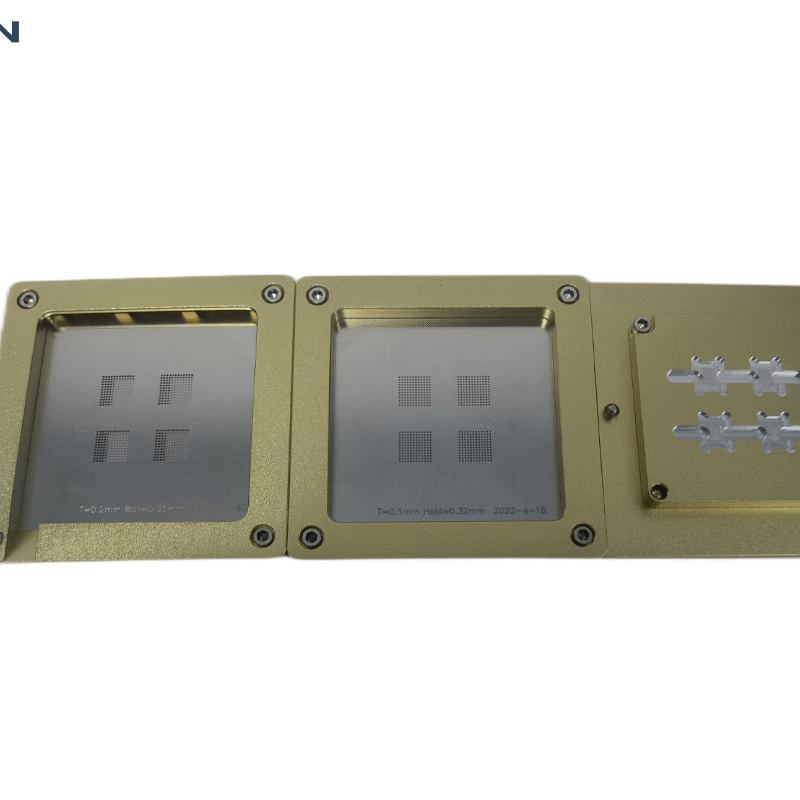

The ST-R820 SMD / BGA Rework Stations feature the latest vision and thermal process control technologies. Printed circuit boards and substrates consisting of components such as BGA’s, CSP’s, QFN’s, Flip Chips, Support P08 Small pitch LED beads, Min. 2mm * 2mm IC.Rework Station

- Stable and Uniform Hot Air Heating System

- Lower Heater Adjustable

- Carbon Fiber Infrared Pre-heater

- High-Precision PID Temperature Control System

- Industrial High-Definition CCD Camera(1.3MP)

- High-Precision Optical Alignment System

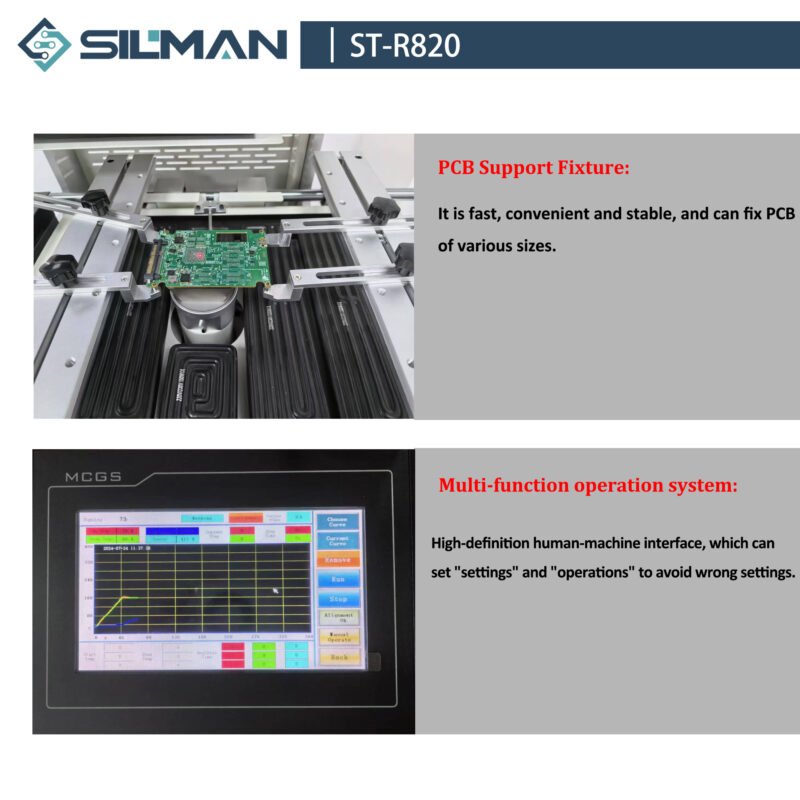

- High-Resolution Touch Screen HMI Interface

- Automatic Placement, Desoldering

- Built-In Pressure Sensor System To Protects The PCB

- Real-Time Temperature Monitoring and Over-Temperature Protection.

- Emergency Stop Button

| Item | ST-R820 |

|---|---|

| Overall Power | 5300W |

| Top heater | 1200W |

| Bottom heater | 1200W |

| IR heater | 2700W |

| IR Heating Area | 280*380mm |

| Voltage | AC220V±10% 50/60Hz |

| Motion Direction | Z Axis |

| Temperature control | K-type Closed Loop thermocouple with accuracy within ±3 ℃ |

| temperature precision | ±3 degree |

| PCB size | Max 415*370 mm Min 65*65 mm |

| Optical system | Japanese original high-definition CCD color imaging |

| BGA chip | Max 80*80mm Min 2*2 mm |

| Dimension | L680*W630*H900 mm (LCD stand not included) |

| Net weight | 79KG |

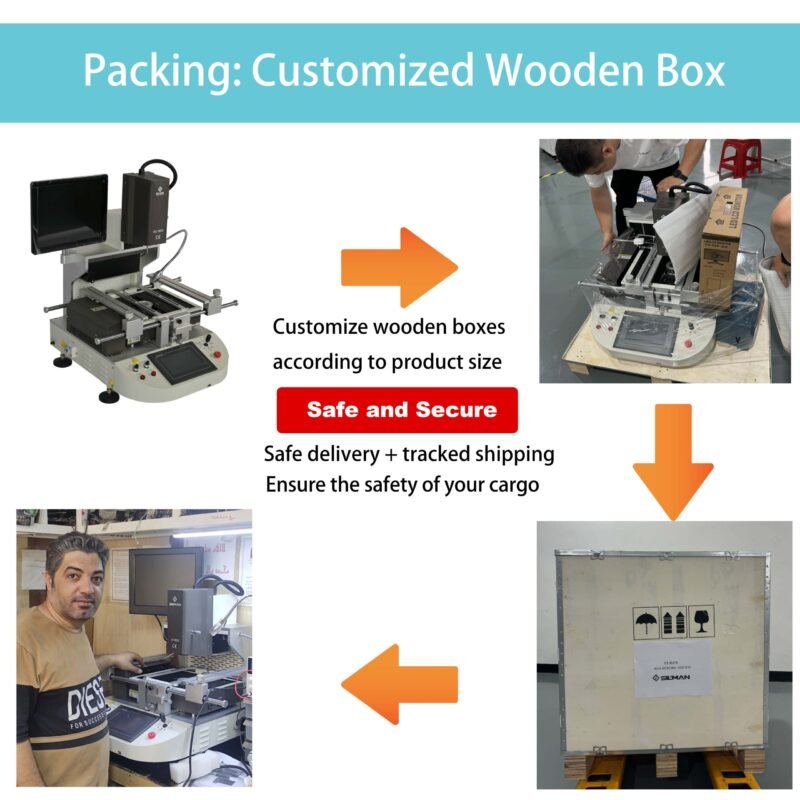

| Packing | L780*W800*H1090mm |

| Gross Weight | 105KG |

- Rework Process Inspection Camera