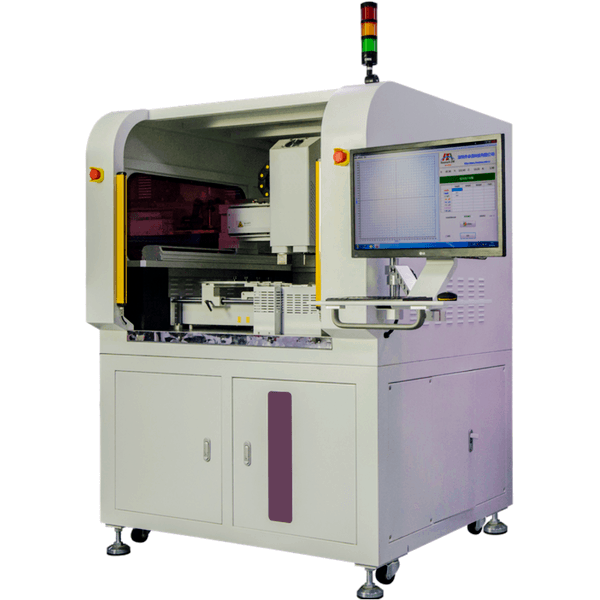

Overview

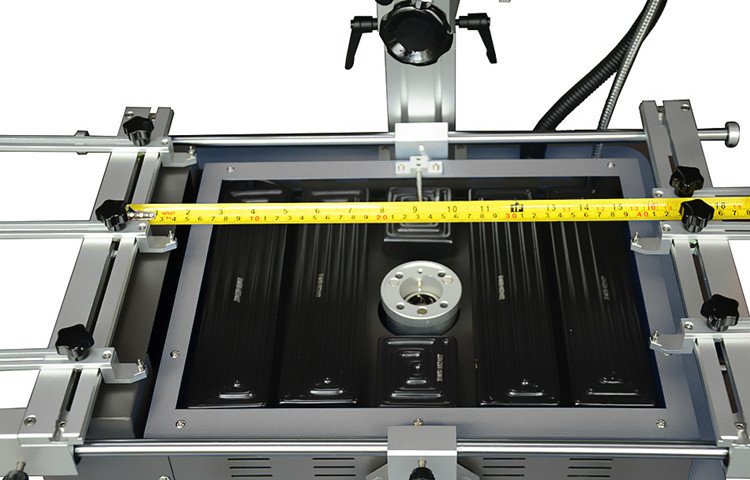

entry level rework system for normal SMD, BGA, QFP, CSP, sockets, Micro-SMD components etc. Support chips size Max. 80mm x 80mm, Min. 3mm * 3mm. PCB motherboard Max. 620mm x 520mm

- Stable and Uniform Hot Air Heating System

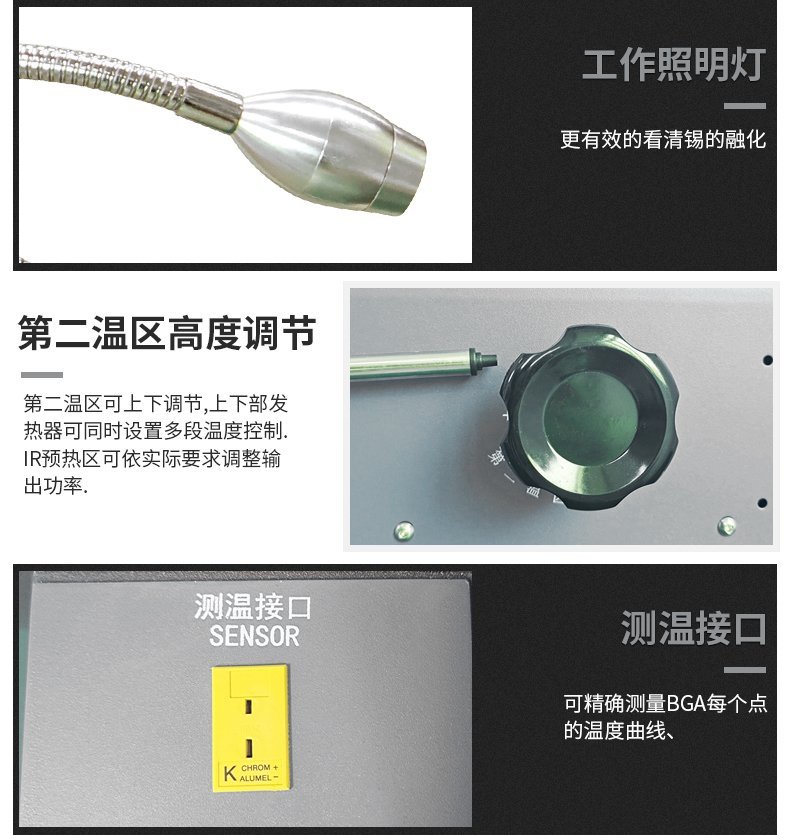

- Lower Heater Adjustable(Height Moving Range 3CM)

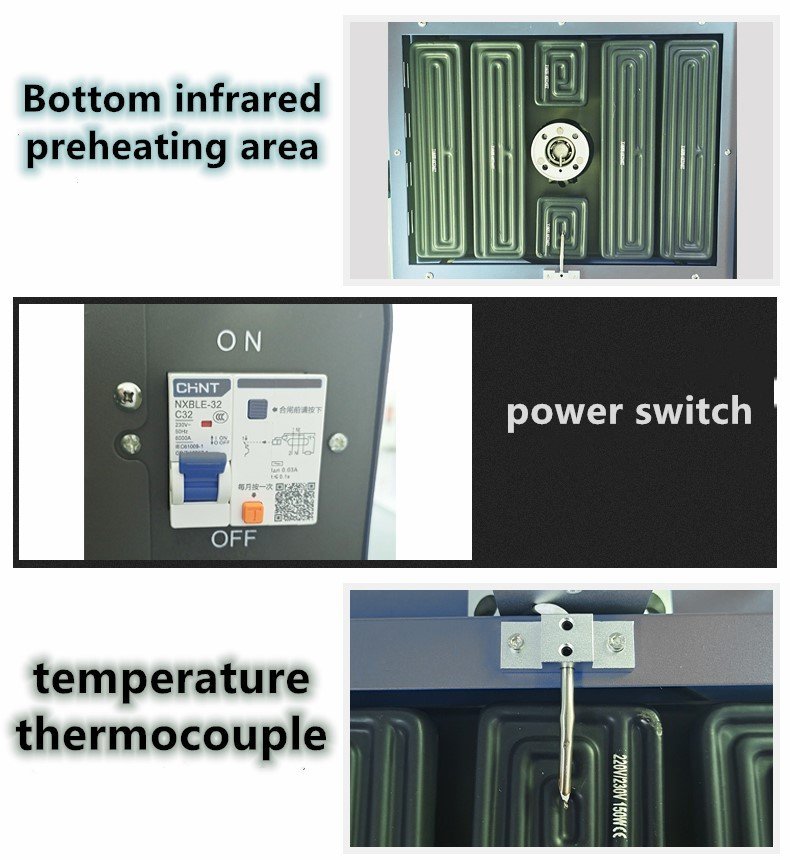

- Ceramic honeycomb Infrared Preheater(Left/ Right Moving Range 30 CM)

- High-Precision PID Temperature Control System(5 K-type sensor, 10 temperature zone control )

- High-Precision Optical Alignment System with Industrial High-Definition CCD (2MP)

- High-Resolution Touch Screen HMI Interface

- Automatic Placement, Desoldering

- Built-In Pressure Testing Device To Protects The PCB

- Real-Time Temperature Monitoring and Over-Temperature Protection.

- Rework Station

- Emergency Stop Function

- Emergency Stop Function

| Item | ST-R610 |

|---|---|

| Total Power | 4800W |

| Upper Heating Power | 800W |

| Lower Heating Power | 1200W |

| Infrared Heating Power | 2700W(1200W is controlled) |

| Power supply | (Single Phase) AC 220V±10 50Hz |

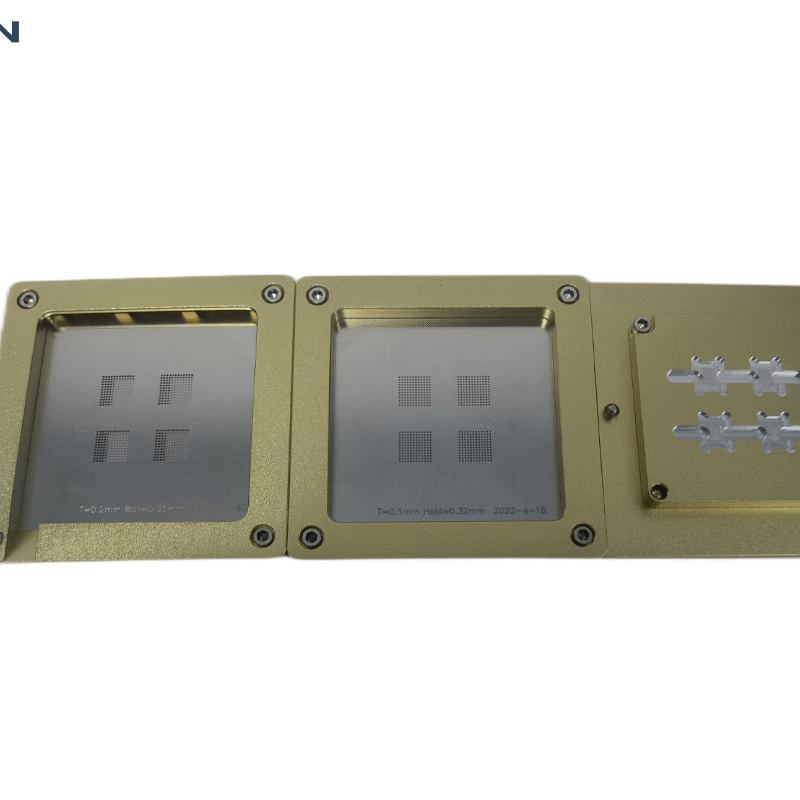

| Location way | V-shape card slot + Universal jigs |

| Temperature Controlling | K-type thermocouple closed loop control, independent temperature control, precision up to ±3 degree |

| Electrical Material | Touch screen + Temperature control module + PLC control |

| Max PCB size | 470*370mm |

| Min PCB size | 10*10mm |

| Sensor | 1 unit |

| PCB Thickness | 0.3-5mm |

| Suitable Chip Size | 2*2mm-60*60mm |

| Machine Size | 500*590*650mm |

| Weight | 40KG |

- Rework Process Inspection Camera