Overview

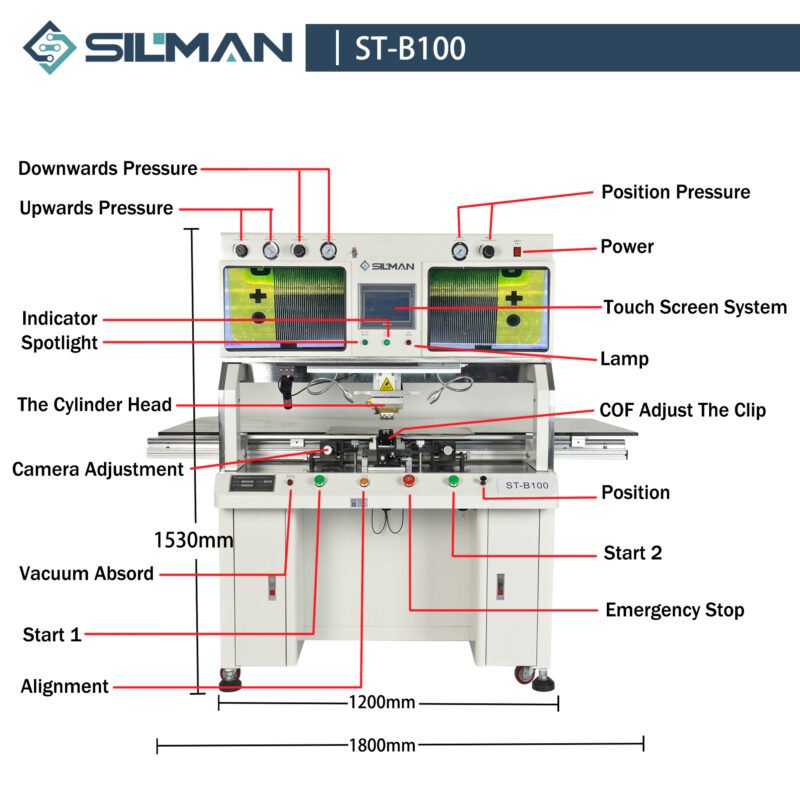

Semi-automated ACF COF Bonding Machine for LCD Tab, COF IC, Flexible Cable bonding.

LCD Flex-Cable COF ACF Bonding Machine – for COF/TAB Repair Bonding Machin

1, PLC control, pulse heating mode, combined with titanium alloy extrusion head, rapid heating and rapid cooling, can be set up four heating, accurate temperature control.

2, 5.7 “color touch screen LCD display input, realizing the temperature curve, according to the Chinese menu, all the parameters set browse concise and straightforward.

3, large load platform, stepper motor drive, multiple IC can be preset position, the platform automatically move the pressure to stay.

4, under the high magnification camera system, ensure that the product clearly counterpoint.

5, easy-to-use software, automatically detect fault and alarm function.

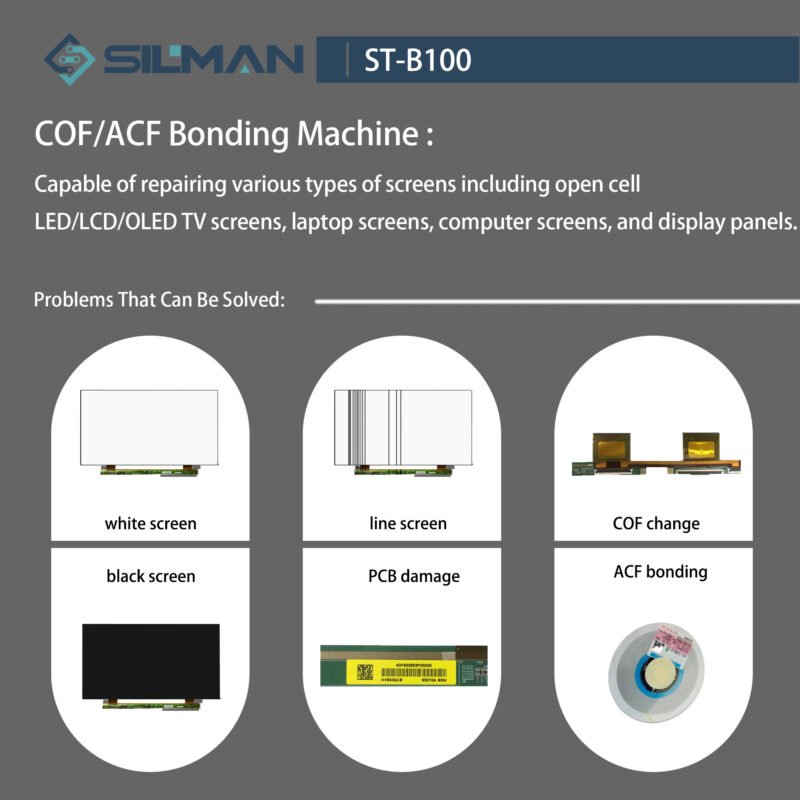

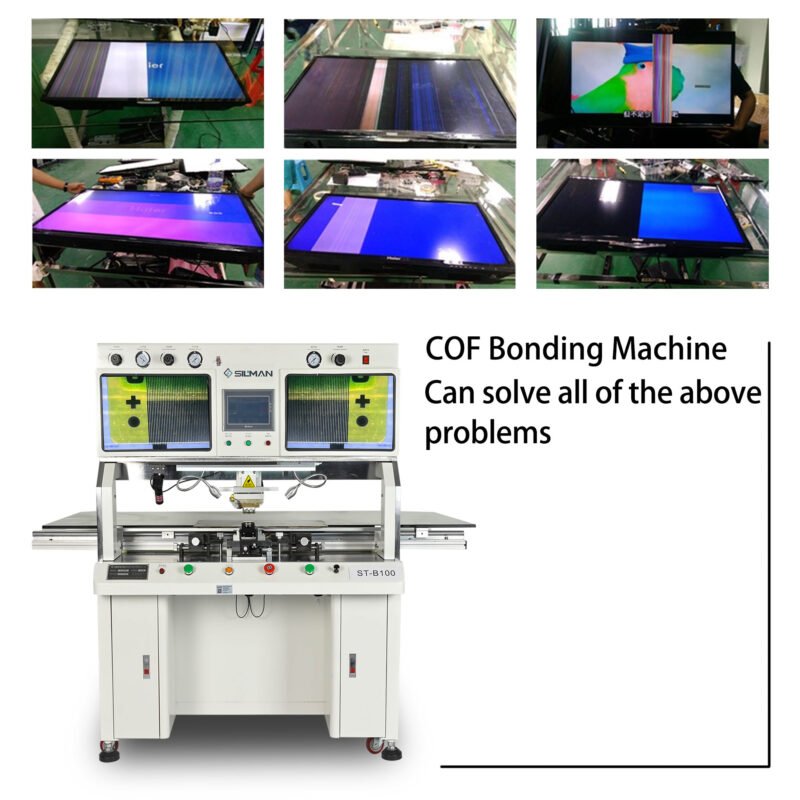

What does it Repair :

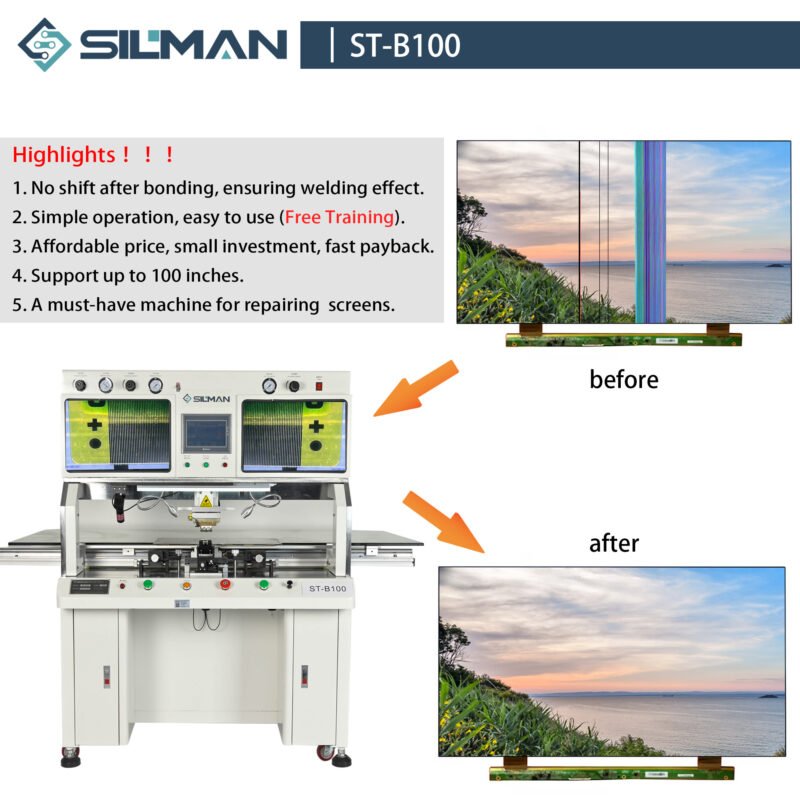

TV screen problems caused by damaged flexible cable including Vertical, horizontal, black belt, the black line, the color line, ribbons, multi-line, flower screen, black screen.

Application: suitable for 12-100 inch TFT Panel and TAB, FPC and LCD or PCB board flex-cable bonding.

| Model number | ST-B100 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Specification | Single Head | ||||||||

| Heating mode | Pulse heating | ||||||||

| Working precision | ≤±0.01mm | ||||||||

| Working capacity(PCS/HOUR) | 28 PCS | ||||||||

| Machine size | 1800mm (L) ×1200mm (W) ×1400mm(H) | ||||||||

| Input Power | AC220V±10%,50-60 Hz | ||||||||

| Rated Power(W) | 4000w | ||||||||

| Work pressure | 0.4-0.8Mpa | ||||||||

| Operation mode | 7inch touch screen control | ||||||||

| Alignment system | 2 High definition C/LCCD camera | ||||||||

| Temperature error range | ±0.5°C | ||||||||

| Programming control device | PLC controller | ||||||||

| TAB fixture | micrometer X, Y, Z Axis adjust | ||||||||

| Platform moving | Manual operate | ||||||||

| Hot press head size | 1.5mm*50mm | ||||||||

- ACF Tape

PCB Camera