In the dynamic landscape of electronics manufacturing and repair, selecting the right BGA rework station supplier is not just a procurement decision—it’s a strategic investment in your product quality, production efficiency, and long-term profitability. Whether you operate a bustling repair shop in Malaysia, a high-volume SMT production line in the USA, or an automotive electronics manufacturing facility in Vietnam, the choice of supplier directly impacts your ability to tackle complex BGA rework challenges. With countless options flooding the market, how can you identify a partner that delivers on promises, understands your regional needs, and provides consistent support? This guide unpacks the critical criteria for choosing a BGA rework station supplier, and why stands out as the trusted choice for businesses worldwide.

Key Criteria for Selecting a BGA Rework Station Supplier

Not all BGA rework station suppliers are created equal. To avoid costly mistakes and ensure a fruitful partnership, focus on these three non-negotiable criteria:

1. Proven Technical Excellence and Real-World Performance

The foundation of a reliable supplier lies in the technical superiority of their products. Beyond glossy parameter sheets, you need to verify how their BGA rework stations perform in real-world scenarios. Critical technical indicators include thermal control precision, optical alignment accuracy, and process stability—factors that directly influence rework success rates and product reliability. Look for suppliers that can provide verified data, such as oxygen content control below 10ppm for high-reliability welding and temperature uniformity within ±0.8℃, which are essential for handling fine-pitch BGAs and complex PCBs. Additionally, ensure their products support versatile applications, from consumer electronics to aerospace components, to adapt to your evolving business needs.

2. Transparent Reliability and Total Cost of Ownership

A low initial price tag can be misleading if the equipment suffers from frequent breakdowns or high maintenance costs. Evaluate a supplier’s reliability by checking the mean time between failures (MTBF) of their products and the transparency of their maintenance costs. Reputable suppliers use high-quality core components (e.g., precision heaters, high-resolution cameras) and adopt modular designs for easy maintenance, reducing long-term operational expenses. They should also provide clear data on equipment lifespan, maintenance cycles, and total cost of ownership (TCO) to help you make an informed financial decision.

3. Strong Industry Reputation and Customer Testimonials

A supplier’s reputation is built on years of consistent service and customer satisfaction. Look for reviews, case studies, and testimonials from businesses similar to yours—especially those in your target market. For example, if you’re a Vietnam-based automotive electronics manufacturer, seek out suppliers trusted by local peers for their ability to handle automotive ECU rework.

Why Dezsmart|Silman Is the Preferred Choice for Global Businesses

When it comes to meeting and exceeding the above criteria, Dezsmart|Silman emerges as a leader in the global BGA rework station market. With decades of experience serving electronics manufacturers and repair shops across Malaysia, the USA, Vietnam, Saudi Arabia, and beyond, Dezsmart|Silman has earned a reputation for excellence, reliability, and customer-centricity. Here’s why businesses worldwide choose us:

Unmatched Technical Innovation

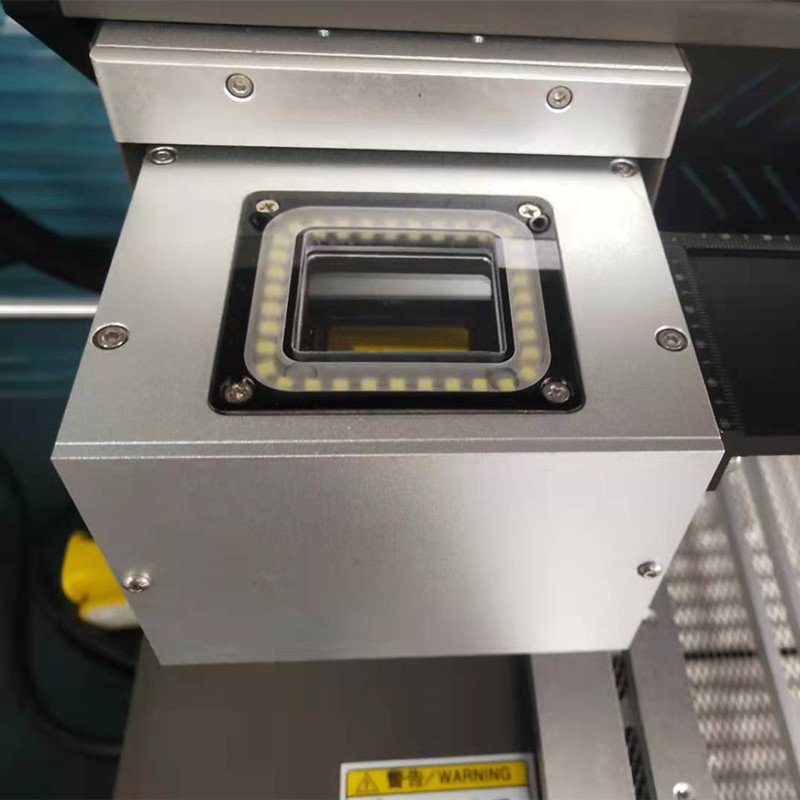

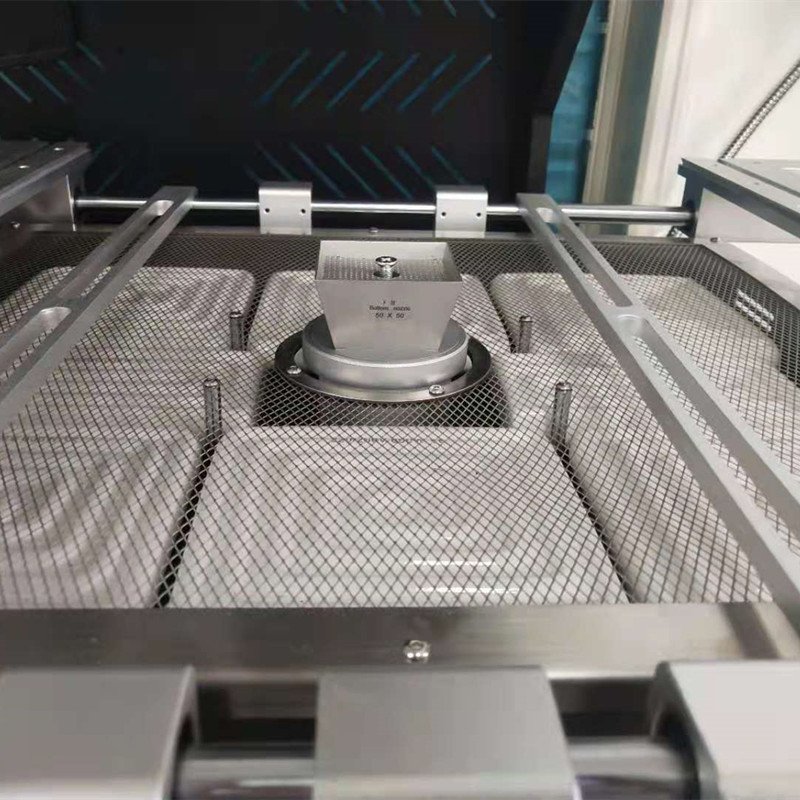

Dezsmart|Silman’s BGA rework stations are engineered with cutting-edge technology to deliver superior performance. Our systems feature advanced three-zone heating with programmable temperature curves, ensuring uniform heat distribution and oxygen content control below 10ppm—critical for minimizing solder oxidation and reducing void rates to less than 5%. The high-precision optical alignment system with laser positioning achieves micron-level accuracy, making it easy to handle fine-pitch BGAs, CSPs, and large-size PCBs up to 120*120mm. Every product undergoes rigorous testing to ensure process stability, with a 99% first-pass rework success rate that has been verified by thousands of customers globally.

Transparent Reliability and Low TCO

At Dezsmart|Silman, we believe in transparency. We provide detailed information on MTBF (over 3000 hours for our core models), maintenance cycles, and spare parts costs upfront, so you can accurately calculate TCO. Our modular design allows for quick component replacement, reducing maintenance time and costs. Additionally, our energy-efficient systems help lower electricity expenses, making them a cost-effective choice for long-term use. Customers in Malaysia and Vietnam have reported a 30% reduction in operational costs after switching to Dezsmart|Silman’s BGA rework stations.

Proven Global Reputation

Dezsmart|Silman is trusted by over 2000 businesses worldwide, including leading electronics manufacturers, automotive suppliers, and repair chains. Our customer testimonials highlight our commitment to quality and service—from a US aerospace company praising our ability to meet strict industry standards to an Malaysian repair shop noting how our stations have boosted their productivity by 40%. As a result, we consistently rank among the top search results for “BGA rework solution Vietnam”, “precision BGA supplier USA”, and other high-volume keywords in key markets.

Partner with Dezsmart|Silman for Your BGA Rework Needs

Choosing the right BGA rework station supplier is a decision that impacts your business for years to come. By prioritizing technical excellence, global support, reliability, and reputation, you can find a partner that not only provides high-quality equipment but also helps you overcome regional challenges and grow your business.

Dezsmart|Silman checks all the boxes—and more. Whether you’re a small repair shop in Malaysia, a large-scale manufacturer in the USA, or an automotive electronics firm in Vietnam, we have the perfect BGA rework solution tailored to your needs. Join thousands of global customers who have elevated their rework capabilities with Dezsmart|Silman.

Ready to find your ideal BGA rework station? Contact Dezsmart|Silman today for a personalized consultation, free product demo, and detailed TCO analysis. Let’s build a successful partnership together.

Keywords: BGA rework station supplier, Dezsmart|Silman, BGA rework station supplier Malaysia, reliable BGA repair solution USA, BGA rework solution Vietnam, precision BGA supplier, global BGA rework support, SMT rework station supplier